|

KEVIN'S SONEX AIRCRAFT PROJECT

The Sonex is a modern two-seat homebuilt aerobatic aircraft designed for the experimental light-sport category.

| stall | cruise | vne | climb @ aero | fuel | range | empty | gross @ util | limit loads |

| 35 kts | 148 kts | 170 kts | 2000+ fpm | 60lt / 42kg | 345 nm | 280 kg | 520 kg | +6/-3G

@ 950lbs/430kg |

| 40 mph | 170 mph | 197 mph | | 16gal / 92lbs | 400 mi | 620 lbs | 1150 lbs |

| 65 kmh | 270 kmh | 320 kmh | 10+ m/s |

| 640 km | | |

Sonex Aircraft website |

Other builder's websites |

SonexTalk email group

| Site Map

PROJECT STATUS: February 2012 (still 884 hours...)

|

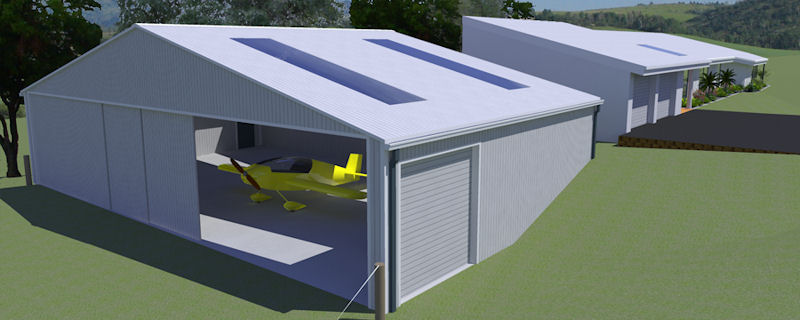

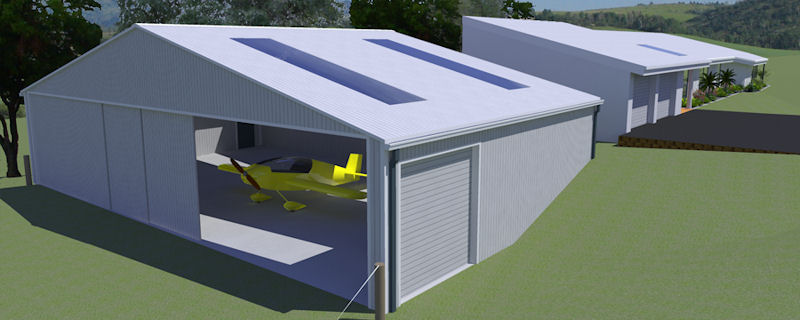

Not a lot of work on the Sonex in the last 8

months I'm afraid, but some small progress towards a workshop /

hangar. There was a LOT of discussion about what it should look

like, what it should be made of, where it should be cited, how

it should be oriented etc. etc...! We had a lot of trouble

imagining what it would look like next to the house, so

eventually I had a number of sketchup models created (I can

recommend Joe Malone for

this type of work), which led us to decide on something like

this:

|

PROJECT STATUS: June 2011 (884 hours)

|

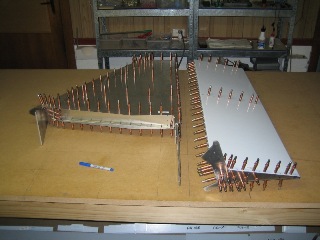

May/June saw the aft fuse box come together

fairly quickly, as I had already finished most of the parts

before the last move, back in May 2009 (!!). I just had a few

holes to cut in the side skins, install the rudder cable guides,

do some tidy-up and then work out all over again how everything

fits together! In my rush to get things finished

and packed before moving, I made a mistake in 2009 by drilling

all the upper longeron holes to final size (#30). They should

stay at pilot size (#40) until the turtledeck has been fitted,

so I had to be extra careful when drilling the turtledeck to the

longerons, not to enlarge the existing final-size holes. I got

away with it, but it highlighted the need to carefully look

ahead in the plans and understand the next few steps ahead of

time. After a lot of stomach crunching exercises

fitting the turtledeck formers I eventually got everything

fitted and drilled and clecoed. I've now taken the turtledeck

assembly off again for deburring and corrosion proofing. July

should see it back in place with rivets. Latest

panel concept with MGL Voyager, VHF & Trig Transponder. Although

I'm hoping to use the MGL transponder if it is ready:

|

|

PROJECT STATUS: May 2011 (832 hours)

|

It seems impossible, but the last entry in my

builders log

is dated October 2009 - a year and a half ago! Time flies, as

they say. The thing is, I want my Sonex to fly too, so I had

better get back on with it! It has been something of a financial

stretch for us to buy this property with airstrip-in-potentia,

and so the intervening time has been spent... well, stretching!

:-) But things are getting back on track again,

and I've just finished setting up my workshop again (for the 4th

time would you believe, after 3 moves in the last 5 years!). Due

to aforementioned stretch the planned hangar & workshop has not

yet been possible, so I've set-up in the garage for the time

being. Picture at right shows levelling the workbench with a

plastic tube filled with water. Next steps will

be to reassemble and rivet the aft-fuse box and construct the

turtle-deck. Then on to the forward-fuse... A

timely inspiration boost has come from getting to have a fly in

Tim Midgley's Sonex, pictured at right. Thanks Tim - Awesome! It

flies beautifully, although is more pitch sensitive than I am

used to. It also reaffirmed my decision to use the Jabiru 3300

engine and the Prince prop. This was the first completed Sonex I

have seen 'in the flesh', and I also have to say that I was

slightly surprised by how small it seems in the real life. In

fact, while we were pushing it back to the hangar I had a

momentary impression that it was not unlike a large-scale

radio-controlled model!

|

|

PROJECT STATUS: March 2010 (832 hours)

|

Well the 'minor home renovations' I mentioned in

May somehow evolved into a year-long effort culminating in the

purchase of a new property! So there has basically been zero

progress on the Sonex for the last 10 months. I did get the aft

fuse parts alodined, but that's about it. The Sonex is

partially responsible for this latest move actually, as I wanted

somewhere I could build a Sonex-suitable airstrip. It was not

easy to find! But - our new property has an area that I think

will work. It's only about 300m/1000' and is on a bit of a

slope, so one-way, but it should be fine for the Sonex in most

conditions that I will be flying (read as: good weather!).

It will probably take the best part of another year before I get

back to work on the Sonex, as I want to build a proper

hangar/workshop here, directly off the left end of the house,

opening into the 'airstrip paddock'.There are also plans for

some horse yards and stables and a few other miscellaneous jobs

to do before that. So I'm thinking of this time as a 'long term

investment' in the Sonex! I'll add another section for 'hangar

construction' when it gets underway... |

|

PROJECT STATUS: May 2009

|

The aft fuselage box is well on the way. I had

hoped to have it finished and riveted, complete with turtledeck

by the end of the month, but it'll probably take until next

month now. I haven't riveted anything yet as I need to

disassemble for alodining and priming prior to final assembly.

Some minor home renovations and replacing all the guttering on

our house is slowing the Sonex down a little, but I am informed

that preventing it raining in the kitchen whenever it rains

outside has a higher priority! Unbelievable, I know... ;-)

I'll get some pictures loaded into the fuse construction pages

soon... |

|

PROJECT STATUS: April 2009

|

Well it took a few extra weeks to get around to

it (we went on a short holiday in Fiji) but I finally got the left

wing-tip on today! So the left wing is now done, wrapped in

plastic and stored up in the top shed with it's mate.

I now have the wings, tail and all control surfaces completed,

so the only major part of the airframe left to build is... the

FUSELAGE! I sure hope it's true what they say about the

fuse being much easier and faster to build than the wings... :-) I've started

organising all the parts to make the aft fuselage section.

I cut most of the channel parts to length back when I first got

the kit in 2005, but they now need to be completed, along with

some small parts that go together to make the aft fuse sides. |

|

PROJECT STATUS: February 2009

|

My 2009 goals are going well so far:

Sonex right wing is finished and installed for now up in the

wood shed roof frames, awaiting a mate and a fuselage. Left wing

has the frame riveted and now only requires some wiring and

final skin installation to be complete. Should be done with it

and started on the fuselage by the end of March.

My weight is down from 85kg to 78kg, so only 3kg to go.

Sojo & I completed our first 40km endurance

'training' ride on Feb-28 with a perfect vet through at the end.

Another 40 and then three 80km rides to go before he's

qualified.

|

|

|

I've also been playing around with

Xpanel and have a

new panel layout. I

bought an OKI C5650 colour printer last year, which can print

out Sonex size panels at full scale onto a single 216x900mm

sheet of banner paper. I've moved the Voyager left of centre to

try and minimised crossing of arms (right hand on centre-stick,

left hand pushing buttons).

|

PROJECT STATUS: January 2009 (675 hours)

|

Well, I seem to have well and truly overshot my

2005 New Year Resolution to build a Sonex by the end of that

year... ahem! But, I'm now very close to having the wings

finished and am going to renew my new year resolution for 2009 -

I will have the airframe finished and the engine in my workshop

by this time next year. My other major goal for

2009 is to qualify my 5 year old Quarab "Sojo" to compete in

endurance rides. And get my weight from 85kg back down to 75kg.

I think both Sojo & the Sonex will appreciate that one! In the meantime,

I've begun riveting the right aft wing skins on! The right wing

should be well finished by the end of January. |

|

PROJECT STATUS: October 2008 (603 hours)

|

I've now Alodined all the wing ribs,

gussets and aileron bellcrank parts. Currently riveting the

gussets to the ribs and making the #9 rib aileron bellcrank

assembly. Next will be riveting the ribs to the

right-spar, adding wiring conduit, static/pitot/aoa lines and

wing tank plumping... |

PROJECT STATUS: September 2008 (583 hours)

|

Have been deburring wing ribs and associated

parts. Nearly ready to alodine all the wing parts prior to

reassembly and final riveting. I've also uploaded a lot of new

pictures to the construction area and am in the process of

adding comments to all pictures. |

PROJECT STATUS: July 2008 (573 hours)

Wing spars riveted and mated!

I found that a 1/2" diameter bolt seemed to set rivets better

than the 3/4" bolt, and I also stopped using the 5/32" squeezer

set, sitting the head of the rivet directly on the bucking-bar.

The head gets flattened slightly, but I think it actually looks

better, and the Sonex literature says it has no affect on the

strength. |

PROJECT STATUS: June 2008 (563 hours)

|

After getting the left wing clecoed together and

all holes drilled to final sizes, it's finally time to set all

those solid rivets in the main spar assemblies.

Despite earlier thoughts of using a c-frame tool for this, I

decided to try the Sonex suggested 'hammer and bolt' method,

which so far is proving quite satisfactory. I started at the

outboard end of the spar, thinking that my 'hammer' technique

would improve as I went and the outboard rivets would be less

critical (under least stress). I drilled a hole

in the bucking-bar to fit a

5/32" rivet-squeezer set and then

'back-riveted' the rivet tails with a polished 6" x 3/4" bolt. |

|

PROJECT STATUS: May 2008 (558 hours)

It's taken a while to get

back into building after moving from King Island back to Tasmania,

but I've now started working on the left wing. I'll get it to

the same stage as the right wing (skins clecoed on) and then

take it apart and rivet both left and right main spars before

reassembling the wings for the final (I hope!) time.

I wasn't happy with the fit of the leading edge on the right

wing, and so I tried reforming the left skin by the 'vacuum

bagging' method, with 43mm (1.7") OD PVC pipe forming the

leading edge. It helped, but not as much as I had

hoped - the leading edge radius still seems too large. I'm going

to try reforming it again using smaller diameter pipe. |

|

PROJECT STATUS: November 2007 (513 hours)

Horizontal stab, elevators,

vertical stab, rudder, flaps and ailerons are completed.

Rear wing spars are completed. Main wing spars are completed

except for final riveting. All ribs have been fitted and

drilled, but require clean-up, alodine and riveting.

I've changed my mind again and have decided to build the wings

before the fuselage. I'm currently working mainly on the

right wing. I'm planning to seal up the first few wing-bays in the leading edge

of each wing, to form auxiliary fuel

tanks. These should add another 45+ litres of reserve capacity

for the occasional 'long haul' over Bass Strait.

I will be leaving King Island and moving back to Tassie in

January, so I will probably won't get much more done until

February or so, apart from packing everything into a shipping

container (again!). |

|

PROJECT STATUS: February 2007 (260 hours)

Time for a well overdue website

update! I have now moved to King Island, and after quite a break

am starting to work on the Sonex again. It was quite a packing

job, getting it here! I'm now building in the KI aeroclub

hangar, which means I have a lot more room, but on the other

hand it's not quite as close as it used to be when it was just

'downstairs'. I have returned to working on the

tail section, and have alodined all the sub-structure pieces and

begun to rivet things together. Now that I have more space, I am

planning to build the fuselage before going further with the

wings. I've also ticked off a milestone by

getting my Private Pilot Licence (PPL) and RAA Pilot Certificate

in December. My next goal is a tailwheel endorsement for both GA

and RAA aircraft. |

|

PROJECT STATUS: July 2006 (211 hours)

Still no more progress since April, unfortunately. But, there are

big changes afoot! I am planning to move back to my childhood home

of King Island for a year or so. I am going to take my Sonex project

with me and set up shop in the aeroclub hangar at the airport. I

plan to have a lot more spare time over the next year, and should be

able to spend a lot of time working on the Sonex. I'm slightly

worried about the salty air and relatively corrosive environment on

the island, but I'll use that as encouragement to get parts made,

primed, assembled and painted as quickly as possible!

I hope to make the move around September/October. The only progress

I'll make on the Sonex before then is to pack it all up again, ready

for shipping! Luckily I kept most of the crate material that it was

shipped to Australia in.

So... new construction goal is to have the wings finished by the end

of the year, complete with auxiliary fuel tanks.

Another goal is to (finally!) get around to finishing my Private

Pilot's Licence (PPL) and to also get my

RAA Pilot Certificate along the

way. The RAA license is required to fly RAA registered ultralight

aircraft in Australia. PROJECT STATUS: May 2006 (211

hours)

Yep, well, not a lot is going to happen with the Sonex this month, as I'm now in Boise,

Idaho, in the US for a few weeks. Life is looking pretty busy for the rest of the year

in fact! I'm going to have to be very conscientious in keeping up the Sonex hours when I

get back home. Anyway, there should be more to see by the end of June. Finishing the

wings in July sounds like a good target. PROJECT STATUS: April 2006 (201

hours)

Wing spars are almost ready for riveting. I was waiting on some dimpling and

countersinking bits from Avery in the US for a while, so used that time to mostly build

the flaps. Looks like I may be away most of next month for work, so not expecting to get

a lot done in May. Will have to pull my finger out when I get back! But I still feel

like I'm on track to have it finished by the end of next year. Hopefully...!!

PROJECT STATUS: March 2006 (138 hours)

Unfortunately I've been a bit busy with other stuff and haven't done any work on the Sonex for a couple of months.

But anyway, I've just started on it again,

initially deburring and smoothing the tail parts prior to alodining and riveting, but have put that aside for the time being and have now started on the main wing spars.

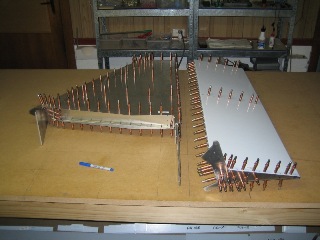

The picture on the right shows both main spars temporarily assembled with 3/32" and

1/8" clecos, ready for final drilling with a #21 drill bit for the beefy 5/32" solid

rivets that are used throughout most of the spar. Starting to think

seriously about how to incorporate leading edge fuel tanks between ribs 1 and 4. Check out the construction pages for more details. |

|

PROJECT STATUS: January 2006 (137 hours)

Happy New Year! If you're a Sonex

wannabuild, I hope you made a determined New Year Resolution, and this is the year you

take your first steps on the journey! :-) I'm 138 hours into construction so far. The horizontal and vertical tail parts have been

assembled entirely with clecos, but are now in pieces again for deburring, smoothing and

corrosion-proofing, before being reassembled for good with rivets.

I've uploaded a lot more pictures into the construction area (accessed via the menu

in navigation pane on the left of the page), but haven't had time to add much

commentary to the newer ones as yet. Also added some recent life images, from around

the Christmas period. |

|

PROJECT STATUS: December 2005 (109 hours)

|

Okay, well it's now a year since I began this website and embarked on my

mission to build a Sonex. As it turned out, I was wildly optimistic to think I could

have the airframe completed this year, not least because it took until October to get

the kit! So I'm basically behind one year, with the plan now being to get the airframe

built by the end of 2006. The biggest potential hiccup with this, is that

I may have to go and work in America for three months to half a year, probably

beginning in February. So my immediate plan is to try and complete the tail surfaces

before I go. I currently have the horizontal stabiliser and elevators

formed and drilled, and am working on getting the vertical stab and rudder to the

same stage, so I can take all the parts to be alodined at a local metal fab shop.

|

|

PROJECT STATUS: October 2005 (53 hours)

|

Yeah Baby! It's here! Whoo-hoo! Early this month I went out to the

freight depot and collected one very large wooden box and a long cardboard tube. The

cardboard tube was actually a bit damaged in the middle, but luckily the spar cap

extrusions inside were fine. At first the box appeared quite a bit larger than I had

been expecting, but after unpacking it and moving all the contents into a spare room in

my house, my perspective changed a little - it's hard to believe there actually enough

stuff there to build an entire airplane - or at least the airframe. It

really is an amazing kit. Virtually everything is here, right down to wheels

and brakes and even seatbelts. And nuts and bolts, counting the Wicks hardware kit.

I simply can't explain how much of an improvement this kit is, compared to what I

had previously been exposed to. The laser cut skins look fantastic, complete with

smooth curvy edges and thousands of pilot holes, all in perfect position! The wing

ribs are almost perfectly flat, the flanges perfectly formed. The flanged ends even

have pilot holes in them. I am so pleased I bought the full kit, I just can't

overstate it. You can see some of the laser-cut parts in the picture

on the right, laying in the pallet. There are actually eleven layers of these parts

in the pallet. I had to take them out layer by layer to get them inside, as I could

lift the pallet in through the doorway. I unpacked the contents of a

couple of the boxes which had more interesting inventory lists, and put the parts on

a shelf. I tell you, this is better than Christmas when you were a kid! :-)

Something I've changed my mind about though, is that I've gone from wanting

dual-stick controls to wanting a single stick setup. The Victa that I did some

aerobatic training in had a centre-stick and I liked it a lot. Plus the "sitting in

the middle" thing when flying solo has a lot of appeal. These thoughts have been

reinforced by the people I have spoken to with single stick Sonexes - they prefer

it. So I'm going buy the single stick welded parts and hardware and try to get them

sent to Australia inside someone else's crate. Anyone importing a Sonex kit??

The only frustration in all this, is that it looks like I am going to have to go and

work in the USA for half a year or so very shortly, and so I won't be able to make a

proper start on the construction until I return. Because of this I haven't unpacked

the kit as much as I otherwise would. What else is new? Hmm.. oh -

the new Dynon

EFIS-D100 looks like it's now shipping. When I pulled the instrument panel out

from the laser-parts, I was surprised how small it is! It looks to me like it's for

a single place aircraft! (Centre stick thoughts again...) I had

virtually made up my mind I would spend the extra money and get one of those snazzy

looking GRT EFIS Horizon 1 instruments,

but now the Dynon looks like a serious contender also. No doubt there will be even

more choice by the time I am ready to install something.

|

|

PROJECT STATUS: September 2005

I am told my kit is due into Melbourne on the 29th. I'm guessing another

week or two to get it from there down here to Tassie. And I received a big bill for the

GST last week. So... not long now! PROJECT STATUS: August 2005

Finally got the money together to pay for the rest of the kit. Hopefully

it will ship out around the end of this week, and should arrive next month! Fingers

crossed! PROJECT STATUS: July 2005

(43 hours) Nearly 50 hours into construction now. I've made all the angle parts to

about 90% completion. I will wait until after I have fitted them to their associated

assemblies and drilled the pilot-holes to final size before getting too pedantic about

surface finish and alodining etc. See the

construction page for

pictures etc. I've added a 'files' section to the menu on the left, and

also a link to a report from the TimerTracker program I'm using to keep track of the

hours I spend on the project. I use this program for work, also... it's a really useful

little utility, but unfortunately is not the most stable program, and crashes annoyingly

often. I still like it though. PROJECT STATUS: June 2005

My angle stock subkit has finally arrived - whoo hoo! I've been modifying Terry Holek's (#590) excellent parts spreadsheet to better suit my project, and should soon be able to begin cutting the angle into the required lengths.

Building begins! Check out the first

construction page for more information. PROJECT STATUS: March 2005

There was a bit of a hiccup in the shipping of Mike's kit, and so my

angle stock isn't now due to arrive here until mid-April. So, not a lot actually

happening yet I'm afraid. Time to start thinking about placing an order with Wicks

Aircraft Supplies, to get some tools and the hardware I will need sent to Sonex-Ltd for

inclusion with my kit. It's a pity that Sonex-Ltd doesn't supply a

hardware kit of their own (as Mustang-Aero does), but I guess this is just the way it is

for now. PROJECT STATUS: February 2005

Hm,

I think I was being somewhat optimistic about finishing the airframe this year, mainly

due to underestimating the length of time it would take to actually get started. So I'm

revising my resolution to one year from when the kit arrives... :-) Hm,

I think I was being somewhat optimistic about finishing the airframe this year, mainly

due to underestimating the length of time it would take to actually get started. So I'm

revising my resolution to one year from when the kit arrives... :-)

I've paid a 1/3 deposit on the full kit, which puts my name in the (12 week!) queue. The

estimated shipping date for my kit is May the 4th. I'm not sure how long it will then

take to get to Australia, but I'll soon find out because Mike Strudwick's kit #759 has

just left Sonex-Ltd, bound for Hobart!

My stowaway Aluminium angle bundle can be seen strapped on top of Mike's bundle in this

picture sent by Mark @ Sonex. So hopefully that should turn up fairly soon and I'll be

able to get started building some of the smaller parts.

This is great for me actually, since I will get to see a full kit first-hand before mine

is shipped. Once I've actually 'seen' what is in the kit, I'll better know what other

hardware etc. I want to purchase from Wicks etc. and have put in with my crate. I am

very grateful to both Mike & the people at Sonex, for being so accommodating.

And...

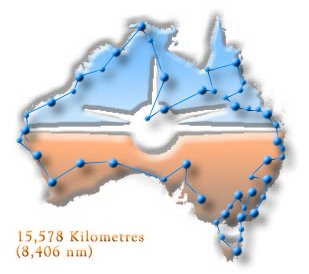

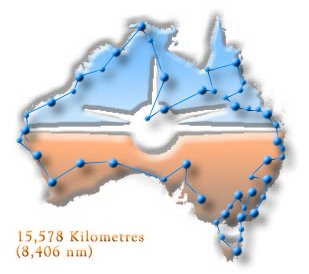

I have entered my (unfinished... actually un-started!) Sonex in the

Great Australian Air Race which is

being held in 2010, celebrating the centenary of powered flight in Australia. Well,

actually they're only accepting 'expressions of interest' at the moment, but since the

race is limited to 100 aircraft I wanted to make sure I don't miss out! Formal entries

and deposits are required next year. And...

I have entered my (unfinished... actually un-started!) Sonex in the

Great Australian Air Race which is

being held in 2010, celebrating the centenary of powered flight in Australia. Well,

actually they're only accepting 'expressions of interest' at the moment, but since the

race is limited to 100 aircraft I wanted to make sure I don't miss out! Formal entries

and deposits are required next year.

I hope the Sonex will be a great airplane to do this race with, as it is reasonably fast

and the operating costs are relatively low - makes a difference when the race is over

fifteen thousand kilometres long!

The Sonex is also slow enough that I hope to be able to admire more of the

scenery than I was able to while tearing along at 220kts in the NZ air-race last year.

Pictures of that race can be seen by going to the 'Life Gallery' menu on the left, or by

clicking here.

PROJECT STATUS: January 2005 (really, this time!)

Okay. It's nearing the end of January. That's 1/12 of the year gone!

How's my NYR going?

It seems it's going to take me at least another couple of months to

get the money together for the full kit, so in the meantime I have

bought the plans only (#776) to get a better understanding of the

project. There appear to be quite a few parts that must be

fabricated entirely by the builder from raw angle and flat stock.

The raw material for most of these parts is contained in the

Aluminium Angle & Flat Stock sub-kit, which is in turn part of the

easy-build

kit.

A builder in Hobart (about 2 hours drive from me) has a full kit on order,

due to ship out of the Sonex factory in just over a week, on Feb-2. The AA&FS that Sonex

supply is relatively cheap (~US$300), so I am trying to organise for

an extra AA&FS subkit to be packed into his shipping crate. If I can

swing it, that will give me some material to work with while I save

up for my own 'big box'!

Not being able to afford the whole thing right at this moment may be

a blessing in disguise, as it will hopefully allow time for me to

get a garage/workshop built, and I'll also be able to check out

Mike's full kit in the flesh before I completely commit to the same

thing myself. I also hope to get over to Adelaide and check out

Lynn

Jarvis' flying Sonex before I place the full order.

So. Looking at the plans, building a workshop and trying to get some

Aluminium! PROJECT STATUS: January 2005 (well, nearly!)

It's the last day of the year. I'm sitting in my tent at the

Marion Bay Falls Festival

at the moment. Walking along the beach yesterday, contemplating

life, I decided there should be no reason why I can't build a

complete Sonex airframe before the end of 2005, so long as I can

organise to buy the full kit very soon. I feel I have enough

experience from building the Mustang-II to jump straight into the

Sonex with a minimum of confused head scratching. If

I can build the airframe this year then I should be able to scrape

together enough money to buy an engine in 2006. Then I've got a few

years to save up to compete in the 2010

Great Australian Air-Race...

:-) So. New Year Resolution for 2005: Build a Sonex

this year. Anyway, some bands I like are going to be

playing soon, so it's time to head back out into the valley.

|

Hm,

I think I was being somewhat optimistic about finishing the airframe this year, mainly

due to underestimating the length of time it would take to actually get started. So I'm

revising my resolution to one year from when the kit arrives... :-)

Hm,

I think I was being somewhat optimistic about finishing the airframe this year, mainly

due to underestimating the length of time it would take to actually get started. So I'm

revising my resolution to one year from when the kit arrives... :-)